Milwaukee Flush Cut Sawzall Blade - Tool Review

Milwaukee Flush Cut Sawzall Blade

This refinement in recip saw blades has been a long time coming. If you're not familiar with the Milwaukee Flush Cut Sawzall Blade, you need to be - especially if you do any rough framing. It simplifies cutting sill plates, window and door rough-ins and probably some other tasks we haven't even thought of.

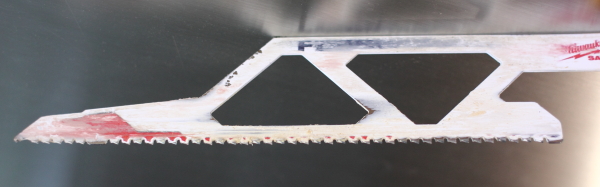

The geometry of the blade is key. There are three distinct features that make this blade unique. The first is the overall web shape (it resembles an ice skate to me). Because of extra surface area, this blade is far less prone to flapping around on the other side of the cut. Vibration is cut to a bare minimum. The blade itself is 9 inches long and 2 inches tall at the widest part.

The wider surface area also lends itself to being a guide for the saw. When cutting through sheathing, the body of the blade rides along the framing member, allowing for a more precise, straighter cut.

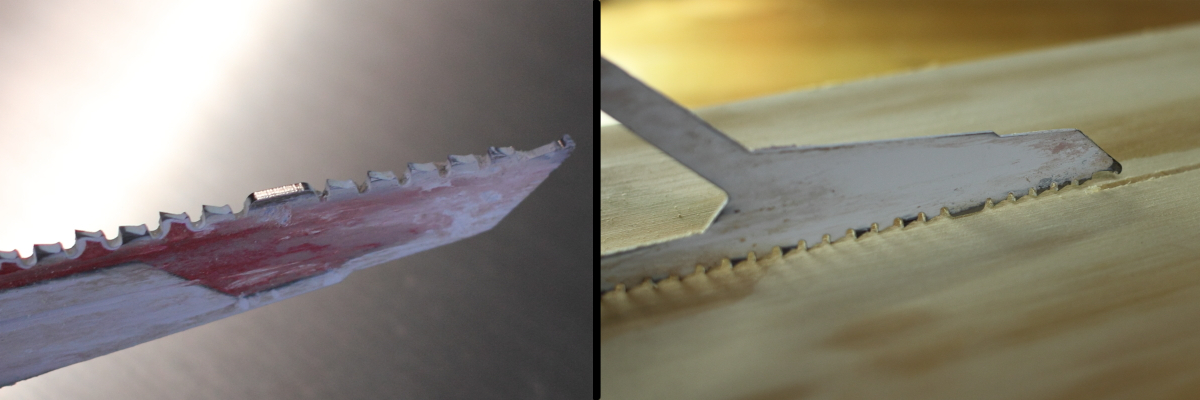

The second feature makes starting any plunge cut easier. It isn't new, but the fact that Milwaukee included it in this design helps. The fang at the tip of the blade grabs the wood fibers more effectively and makes the initial cut easier.

The second feature makes starting any plunge cut easier. It isn't new, but the fact that Milwaukee included it in this design helps. The fang at the tip of the blade grabs the wood fibers more effectively and makes the initial cut easier.

Combine the fang with the third feature and you have a killer combination. There are 2 flat protrusions along the length of the blade (Milwaukee calls them Floor Guard Shields). They sit slightly proud of the teeth at the rear and about an inch back from the front; they prevent damage to sub-flooring when cutting through bottom plates. In the photo on the left, you can see the wear on the Shield. On the right, notice that the teeth of the blade are not touching the wood surface.

Combine the fang with the third feature and you have a killer combination. There are 2 flat protrusions along the length of the blade (Milwaukee calls them Floor Guard Shields). They sit slightly proud of the teeth at the rear and about an inch back from the front; they prevent damage to sub-flooring when cutting through bottom plates. In the photo on the left, you can see the wear on the Shield. On the right, notice that the teeth of the blade are not touching the wood surface.

This double-team makes the blade a superior choice for cutting through bottom plates, as it eliminates the guesswork of when to stop in some situations, as well as the need for using the saw upside down or inverting the blade. Additionally, the blade helps prevent damage to framing when cutting window/door sheathing roughs.

This double-team makes the blade a superior choice for cutting through bottom plates, as it eliminates the guesswork of when to stop in some situations, as well as the need for using the saw upside down or inverting the blade. Additionally, the blade helps prevent damage to framing when cutting window/door sheathing roughs.

I use this blade, albeit not in a production situation, so I'd say your only challenge (especially if you have a crew using your tools) is making sure it's not tossed into a storage situation that would cause bending. Other than that, this is easily a way to speed up some processes and eliminate or cut down on errors or unnecessary damage in others. Plus, at under $20, it's a cheap insurance policy.

Check price on Amazon: CLICK HERE

For specs and more information on this and other Milwaukee Tools & Accessories: Milwaukee Website